What is the current state of Industry 4.0 implementation in the world?

Industry 4.0 implementation in the world

Industry 4.0 (i4.0) is a popular and often discussed topic. However, executives at manufacturing companies need to separate hype from reality. They need a clear picture of the current risks and opportunities. KPMG International has therefore turned to some of the world's leading manufacturers, suppliers, and innovators to get an overview of the current state of i4.0 implementation. The resulting study “Beyond the Hype: Separating Ambition from reality in i4.0” examines the current situation in enterprises.

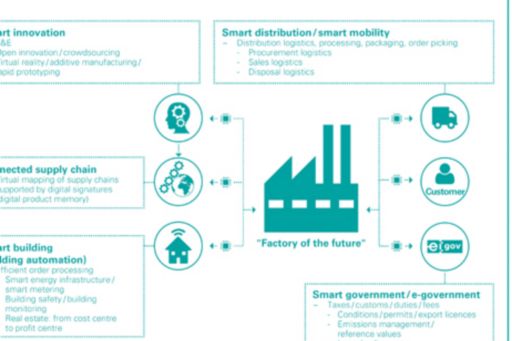

The fourth industrial revolution, known as Industry 4.0, is a shift from digitization to cyber-physical systems through the union of technologies such as Internet of Things (IoT), robotics or big data (picture 1). The concept is based on data collection through scanners throughout the whole product life cycle.

On the one hand, these data allow the producers to quickly respond to current customer demands and at the same time provide insights for the ultimate purpose of using their machines and equipment more efficiently and in an optimized way. According to rough estimates the i4.0 market is to exceed EUR3.5 trillion by 2020.

So the opportunities offered by i4.0 are huge:

- Bring products to market faster

- Machines can perform their own quality checks so errors can be detected and remedied faster

- Optimize equipment maintenance with smarter resource management based on energy data

- Improve stock management through chips and sensors

- Predict demand for products through data mining, and improve supply chain and inventory management as a result

However, full use of these opportunities requires thoughtful investments. It is therefore natural that no company wants to lag behind in building a factory of the future, where information and communication technology and automation technology are fully integrated. All subsystems – including non-producing ones such as R&D as well as sales partners, suppliers and customers are consolidated into one system (picture 2).

Industry 4.0 has resonated for some time now and businesses need to know what their competitors are doing in order to maintain their competitive advantage. In an attempt to generate an overview of the current state of application of i4.0 principles, KPMG International has developed a study „Beyond the hype: Separating ambition from reality in i4.0“, based on a comparative analysis.

The report finds that, while there are many manufacturers working towards creating the ‘factory of the future’ or digital enterprise, few have worked out how to apply those capabilities across all of the corners of their operations. Most are still experimenting with discrete pilots or trialing point solutions.

The benchmarking exercises found that many organizations demonstrated only a low-to-medium level of maturity in key areas such as demand-driven supply chain, machine-to-machine (M2M) communication, and digital twinning. However, they showed somewhat better maturity in cloud, robotics, Big Data, cybersecurity and Internet of Things (IoT) technologies. However, there are still some companies that haven’t developed a roadmap for integrating i4.0 into their business and operating models.

There is no standard template for success in i4.0. It varies depending on - type of customer being served, scale of operation, rate and complexity of production, speed at which organization wants to innovate/compete/develop new products.

But we identified seven main steps that need to be addressed when implementing i4.0:

- Learn what Industry 4.0 concept mean – collect information, best practices, create information base and network of partners for implementation

- Develop a plan of Industry 4.0 implementation

- Identification of benefits

- Risk assessment

- Design a pilot project

- Project evaluation

- Set up a wider Industry 4.0 implementation framework

If you would like to discuss the content of the study, please don not hesitate to contact us at kpmg@kpmg.sk

© 2024 KPMG Slovensko spol. s r.o., a Slovak limited liability company and a member firm of the KPMG global organization of independent member firms affiliated with KPMG International Limited, a private English company limited by guarantee. All rights reserved.

For more detail about the structure of the KPMG global organization please visit https://kpmg.com/governance.