Global sustainability megaforces will mean constraints, complexity and risks for business. The current shortages in the energy or semiconductors industry are just a prelude to what might follow. Business leaders can do much more than simply survive the risks.

Strategic plans should be translated into ambitious targets and actions for energy and resource efficiency, sustainable supply chain management, innovation, and access to new markets for greener products and services to transform a business. Many companies have already worked hard to improve the efficiency of their own processes and operations. The opportunities go beyond the operational boundaries, and working on resilience, in particular in the supply chain, is a key priority.

In the following sections you will find detailed information on these topics:

Definitions

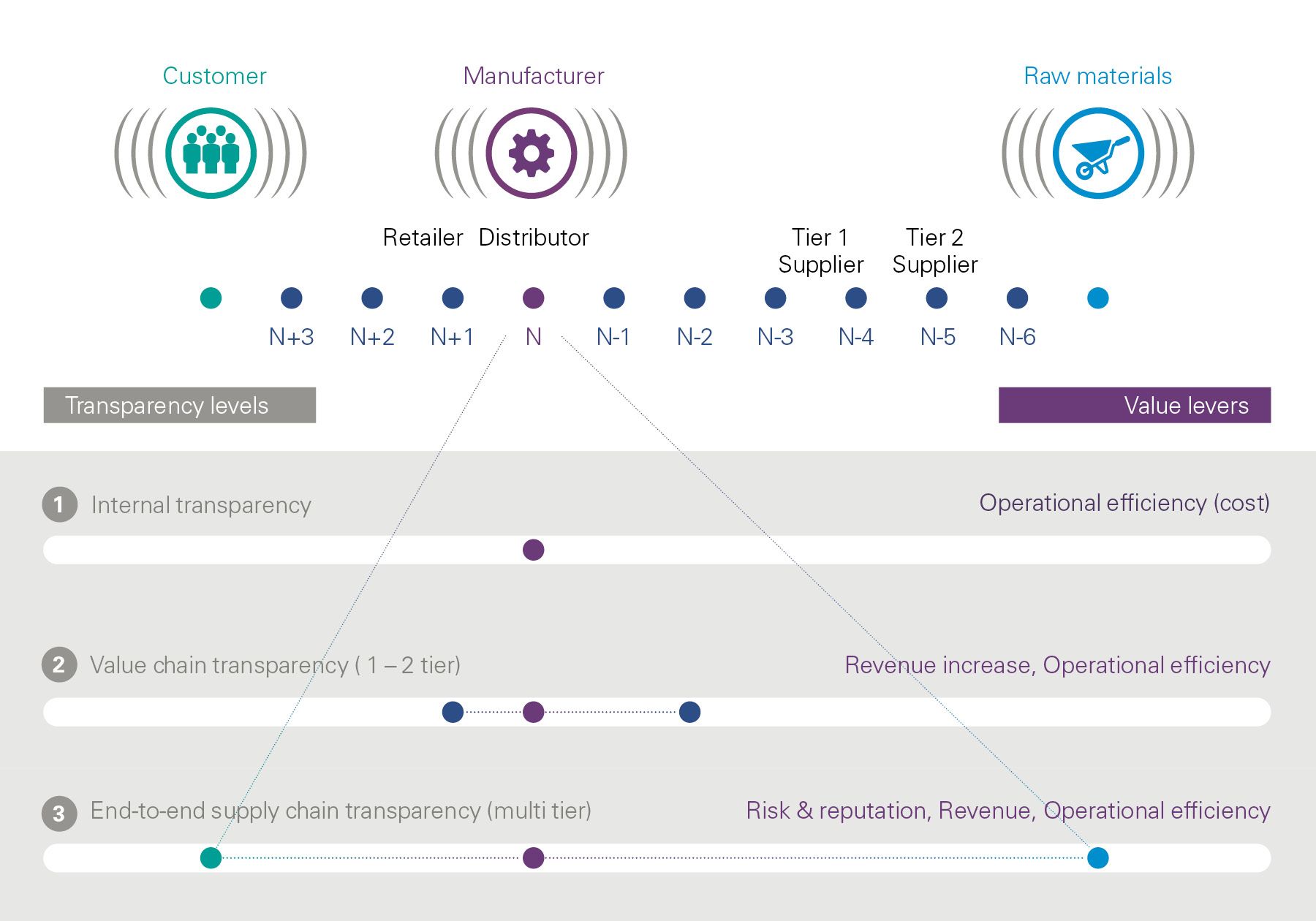

Visibility in the supply chain is the ability to identify and map all steps within the supply chain from Tier n (raw materials extraction) to 1 supplier, distributors, and intermediaries – all the way to the customer or consumer. Transparency is the ability to demonstrate origin, environmental footprint and social aspects throughout the entire supply chain to consumers or other stakeholders. Traceability in the supply chain is the ability to track and trace specific products of batches in every step of the supply chain. Circular Economy describes a paradigm shift from a traditional take-make-waste model towards an approach based on reuse, repair or repurposing of products or materials. |

Supply Chain Sustainability

Some statistics stipulate that more than 90% of companies’ emissions are directly or indirectly linked to their supply chain activities. Due to the global reach and increasing complexity of modern supply chains, visibility and transparency are frequently limited. And there is indeed a lot to focus on: CO2 emissions, child & forced labor, unfair wages, workplace safety, waste disposal, damage to biodiversity, deforestation, single-crop dependency, and much more.

Simply put, not knowing what is happening along a supply chains poses an enormous and increasing risk to organizations. It limits the ability to participate in future opportunities and, at the same time, increasingly threatens existing business relationships. It is, therefore, a key driver for modern businesses to design, manage and operate fully transparent, visible, and high-performing supply chains. Once a supply chain achieves end-to-end transparency, further improvement and advancements can be realized.

The pandemic's disruptive impact on recent supply chain constraints was significant: As per the KPMG CEO Outlook, 76% of CEOs in Switzerland experienced negative supply chain impacts during the last 18 months. At the same time, 68% of Swiss CEOs are committed to acknowledging and incorporating sustainability as a critical future success factor.

Supply Chain Visibility

Visibility throughout supply chains is the prerequisite for both transparency and traceability. Today, most mid-sized Swiss manufacturing companies are operating highly complex supply chains, involving hundreds and in many cases thousands of suppliers. Along this complex chain up to raw materials extraction, insights about handling, security for people, water usage and many others are often lacking.

Solving the information gap is not only vital to ensure efficient and effective production cycles but also securing future access and availability of products. In view of the Swiss Responsible Business Initiative’s counter-proposal by the Federal Council and continuous pressure from multiple stakeholders, transparent and sustainable supply chains will become the new normal. Legislations on various levels (national, EU, global) will certainly propel this development even further. These may include integrated strategic planning, risk management and due diligence on social and environmental matters, for example. The regulatory environment will expand the scope, expectations and requirements of reliable sustainability data and processes in the years to come. As will rapidly increase stakeholder expectations for reporting and disclosure by investors, customers, NGOs, and others.

To establish future-ready supply chains, a five-step approach to insightful transparency and visibility throughout supply chains is needed:

- Identify all stakeholders along complex supply chains

- Define clear roles & responsibilities for each stakeholder – and map all relevant processes

- Identify and align on the overarching business values (beyond the pure supply chain function)

- Advancing supply chains through the interaction model: how do the supply chain partners interact?

- Finally, modern supply chains are powered by technology: gain transparency and visibility all the way from raw materials to the consumer.

Supply chain transparency requires key actors to enable visibility and traceability on multiple levels

Data-driven, digital supply chains are fundamental for visibility and transparency throughout the value chain. It enables improvements in operational excellence, risk mitigation and addressing stakeholder interests – as well as forming a solid basis for assurance.

A new way of thinking – Circular Economy

Another way to think about transformation of a business is to think about the business model itself. The economic opportunities of circular principles are expected to be huge. Supply chains are an essential component in achieving circularity too. Circularity will become non-negotiable in a world where resources are finite, and the climate emergency is pressing.

However, a Circular Economy goes beyond and advocates reuse, recycling, refurbish and repair, and promotes the sharing of products and materials. Circularity is also about shifting people’s mindset towards cognizant consumption and bringing society towards an economy focusing on repurposing, repairing and reusing products. Supply chains play the role of (re)distributing, developing sustainable products from recycled and remanufactured sources, and sustainable manufacturing and sourcing of materials.

Ask yourself the following questions:

- How well do you understand the range of circular economy opportunities available in your organization?

- Are you able to identify circular opportunities that exist outside of waste management?

- Can you confidently incorporate circular economy principles into your strategic organizational plan?

- Are you engaging with the necessary stakeholders to truly maximize your circular economy impact?

How will the new Swiss legal obligation impact suppliers?

63% of issuers expect that suppliers will have to adjust internal processes; 56% that suppliers will have to provide a more comprehensive reporting and 44 % that they will have to amend their Compliance management system.

Findings are from the 9th SWIPRA corporate governance survey, which is conducted annually together with researchers from the Department of Banking and Finance at the University of Zurich and concurrently surveys institutional investors and listed companies. KPMG supports this survey. www.swipra.ch/survey

Further information

Future-ready supply chains are customer-centric, can operate in the ever-changing digital world with agility and do so profitably in order to be a revenue driver for the business. We believe that future success for supply chain depends upon being purpose-built and built to last. Talk to our ESG experts.